Nutrient Recycling and Circular Economy

Circular economy practices help reduce the environmental impact of fertilizer production while also conserving resources and supporting a sustainable agriculture.

Waste management and recycling are key to increase the recovery of nutrients from various residual streams for their reuse in agricultural production.

Fertilizer producers continuously work to optimize their use of resources and incorporate some by-products in the production process, turning them into valuable plant nutrients, and using surplus energy and raw materials that derive from other production processes.

Carbon capture and reuse

The capture and re-use of CO2 emitted by fertilizer plants has enabled production sites to measurably and consistently reduce their GHG emissions from fertilizer production. IFA members around the world not only capture hundreds of thousands of tons per year, but more and more producers are developing sound expertise in conditioning, handling, and transporting CO2 to be sold to other industries (e.g., soft drinks industry). Many of them are also working with regional governments around their sites to share their experience in handling CO2.

Nutrient recovery

The fertilizer industry is actively pursuing phosphorus recycling to reduce stress on natural resources while supporting a sustainable agriculture and the circular economy. These projects will enable the industry to be less dependent on mining and remove secondary phosphorus from waste products that can have an environmental impact while also meeting new regulations. Several projects are under way to retrieve phosphates from alternative sources for the production of phosphate-based fertilizers on an industrial scale by recovering phosphorus from meat, bone and sewage sludge ash and as well as struvite.

Land reclamation

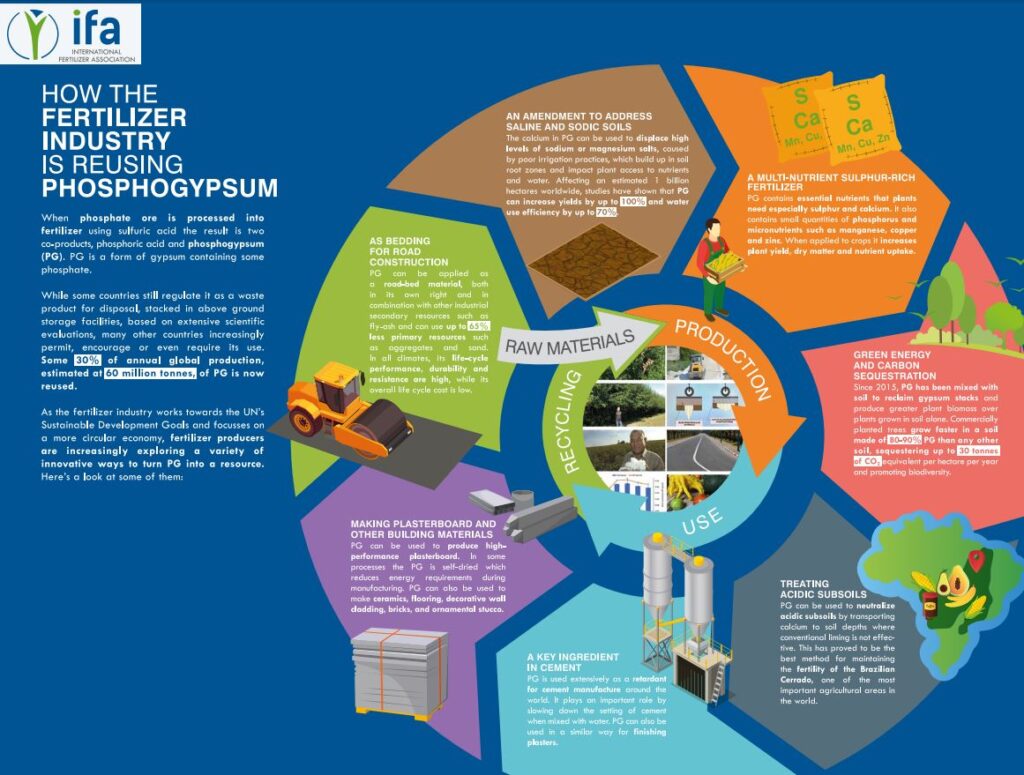

Phosphogypsum, from waste to inventory

The fertilizer industry is now pursuing the total reuse of phosphogypsum as a safe, reusable resource for which there are many beneficial uses, such as a multi-nutrient sulfur-rich fertilizer, high-quality plaster or wallboard, or as a road-bed material.

Different countries regulate PG differently, but in the majority of PG producing countries such as Brazil, Canada, China, India, Russia, Morocco and Belgium, the industry has been working with academia to review and revise the approaches to its use. In some countries, such as Brazil and Belgium, re-use is reaching 100 percent.

You can find out more about the sustainable management and reuse of PG through our two public reports, infographic and webinar: